Acomplete line of in-house filling equipment for aerosol and liquid products.

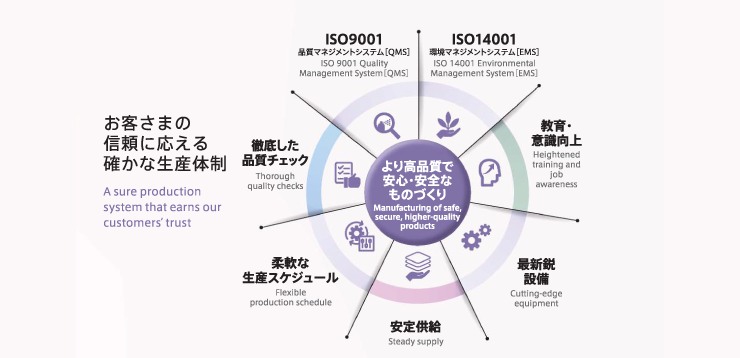

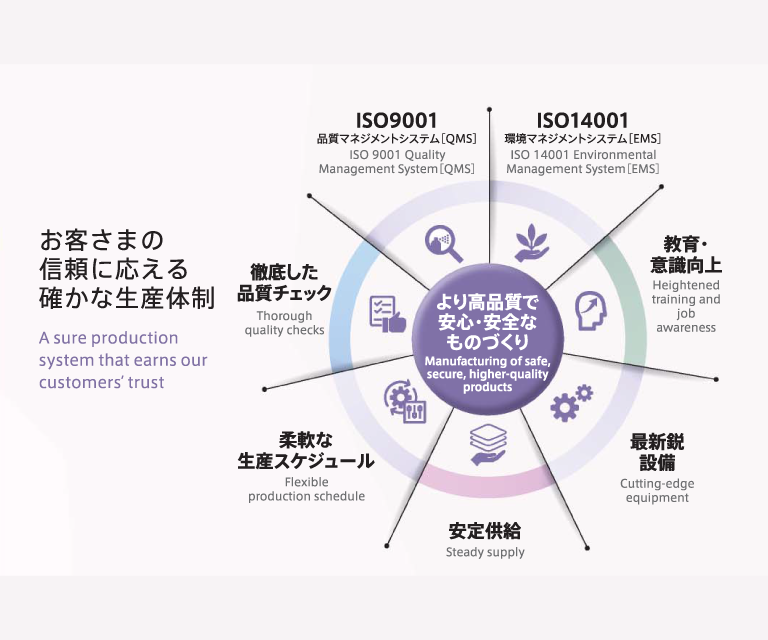

We have a completely integrated production system for compounding,

filling, wrapping, packaging, inspecting and shipping our products.

In considerration of the environment, we perform quality inspections of each process,

quikly supplying reliable, high-quality products. We satisfy our customers' needs with flexibility,

being equally well able to fill orders in small lots and for multiple item types.